HARDWARE PRODUCTS

VIO SYSTEM

Tests of embedded systems often require complex and expensive test solutions, which is why they are only used in the later phases of the development process. With the VIO System, I/O testing can be performed much earlier.

Its compact design makes it ideal for use on the laboratory bench, enabling continuous testing and simulation at evaluation board level even in the earliest stages of development. Whether sensors, actuators or complete ECUs need to be tested during the HW/SW development phase, the VIO System covers all possibilities.

VIO SYSTEM Advantage

- Very compact size directly for the developer's desk (63 HP and 42 HP housings)

- High scalability thanks to modular concept and cascading of housings

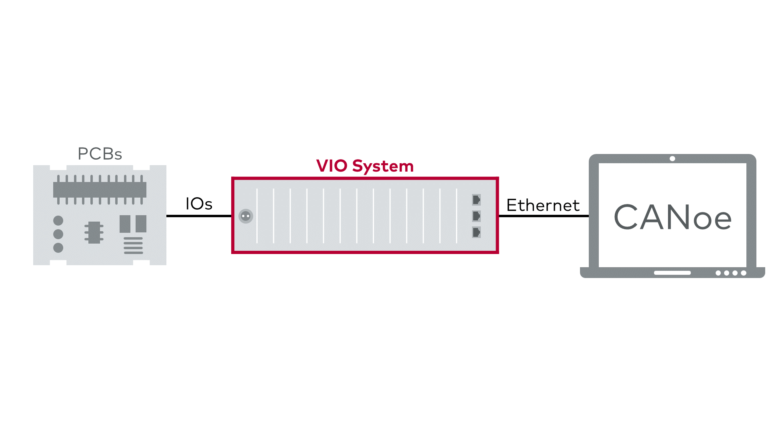

- Seamless integration into CANoe

- Automatic detection of new card types in CANoe

- Tool-free wiring with the target hardware

- Modular expandability due to continuously growing board portfolio

- Support of bus systems through VN interfaces or the integrated VX1161 cards

- Time sync of all cards via IEEE1588 Precision Time Protocol (PTP)

VIO SYSTEM Application Area

In the early stages of development, testing of embedded systems is often limited or impossible because the target hardware is not available, and development typically takes place on evaluation boards without suitable test systems.

The VIO System solves this problem. It is designed to enable faster identification of hardware / software problems through early testing, reducing the need for extensive system-level HIL testing.

Its versatility means it can be used in a wide range of industries. Wherever I/O tests are required at the workplace, whether in the automotive, aerospace, railway, medical or industrial sectors, the VIO System can find and fix errors faster.

Integration Tests at Board Level

The VIO System is ideal for testing system components at an early stage of development in an environment close to reality. Its handy size allows it to be used at any developer’s workstation for rapid error detection and correction.

Within the V-model, the VIO System focuses on integration testing and enables complete test cycles to be repeated in a short time. This can significantly speed up test runs, especially when run in parallel by large teams.

Scalability

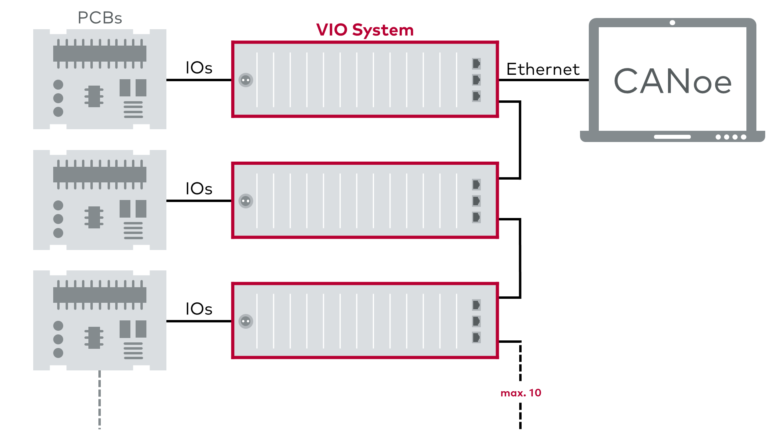

The VIO System housing can hold up to 12 plug-in cards. If more I/Os are required in a test project, cascading is the method used to set up a system of multiple racks. Each additional VIO System is connected to the host uplink card of the previous system, allowing up to 10 racks to be daisy-chained.

When updating individual signals during cross-unit testing, only a subset of signals need to be retransmitted, significantly reducing data rates. The entire system is controlled by CANoe. Configuration is as automatic and intuitive as with a single VIO System.

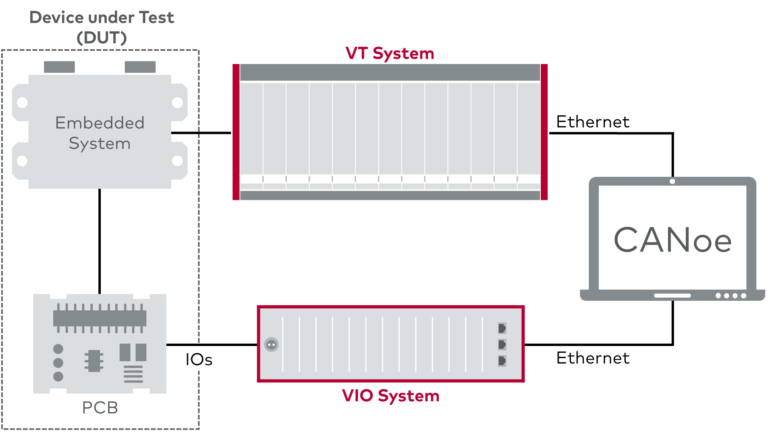

Integration of New Hardware Into Existing Systems

When integrating new hardware into an existing system, it may be necessary to test the new hardware with the VIO System, while at the same time verifying the reaction of the existing system to the new hardware with an existing HIL test (e.g., using a VT System). A big advantage for the user: The integration and operation of both systems takes place in a single CANoe instance.

VIO SYSTEM Housing

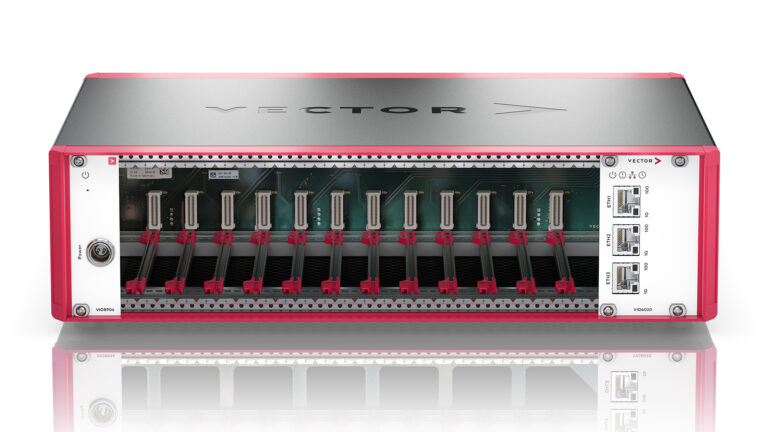

VIO9007

The VIO9007 provides 9 card slots. One slot is dedicated for the power supply card, another one for the host uplink card. The remaining 7 slots are designed to hold any of the I/O cards or can be left unpopulated.

VIO9012

The VIO9012 provides 14 card slots. One slot is dedicated for the power supply card, another one for the host uplink card. The remaining 12 slots are designed to hold any of the I/O cards or can be left unpopulated.